0421 2426440 / 2426441 www.trendzfashions.in

INFRASTUCTURE

We have a range of machineries and systems that drive our production. You can know more about them in the ensuring details

We are following 4 point inspection method for the griege and finished fabric using a light table.

Machinery and software by Morgan Technica, Italy for digitally photographed pattern making with grading and plotting upto 96". Spreaders from Morgan Technica, Italy. A pin table for line/plaid matching. 138 sewing machines including all special equipments made by Juki, Kansai & Brother. All overlock and flatlock machineries are direct drive with semi dry head and lint collector. Which ensures minimum oil stains on garments. 10 steam vaccum tables. Automatic compressed packing machine and needle detector comprises our production floor.

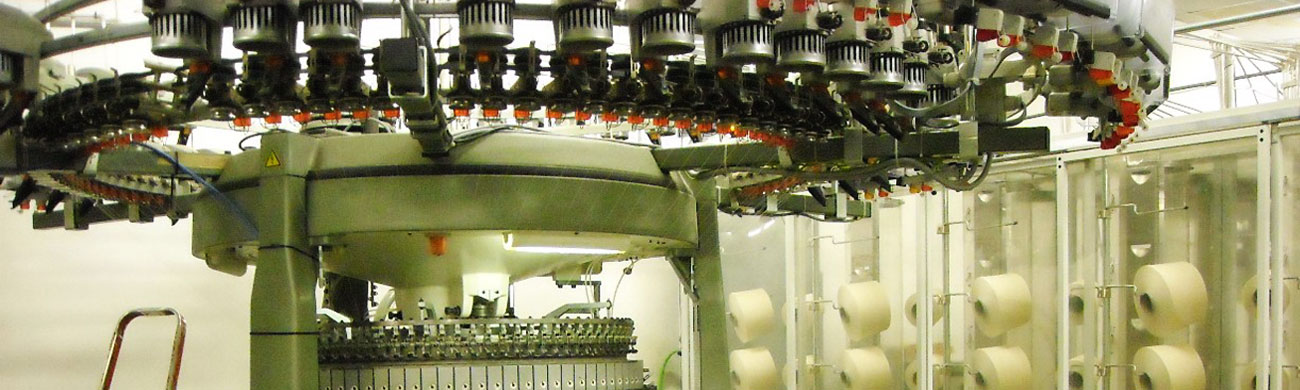

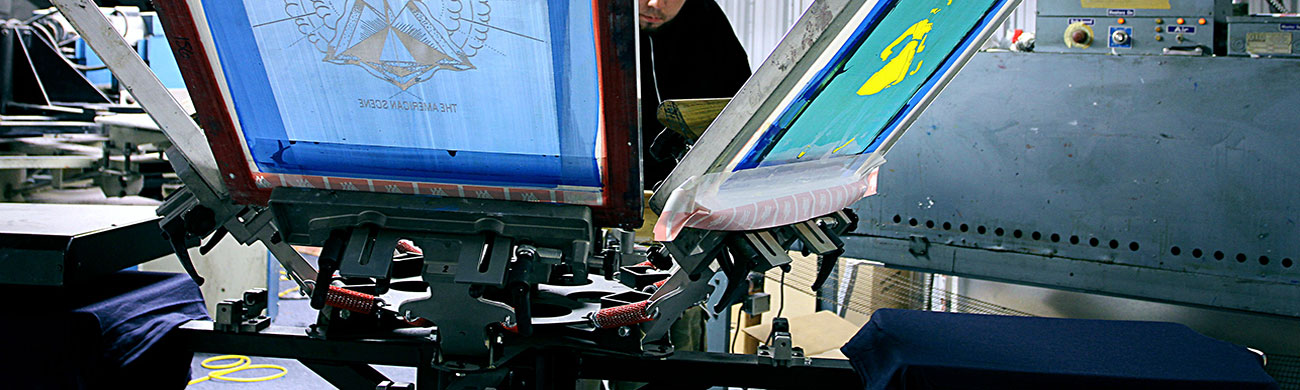

The job of quality assurance team starts from Yarn inwards and it runs through the various stages viz., fabric, sampling, cutting, trims, and accessories, sewing and finally finishing. We have value addtion equipments like fully automatic Japanesh embroidery machines, semi automatic and manual printing machines, Rotary printing, Garment dyeing, washing and hand sewn emblishments. |

|

Click the below thumb images to view the zoom image with description.